Proven quality.

Is a feature of outstanding work

Our customers get to benefit from our large production spectrum for contract forging. At every process stage, ranging from forging the raw material supplied, heat treatment, the precision sizing of pipes or screws, machining and nitriding. We complete your order professionally to the highest quality in a good and workmanlike manner.

Hardness tests

- Brinell according to DIN EN ISO 6506-1 and ASME SA 370

- Vickers according to DIN EN ISO 6507-1

- Rockwell C according to DIN EN ISO 6508-1 and ASME SA 370

- Hardness depth of heat-treated parts (Nht/NHD) in accordance with DIN 50190 Part 3

- Mobile hardness test “Equotip” and “Microdur”

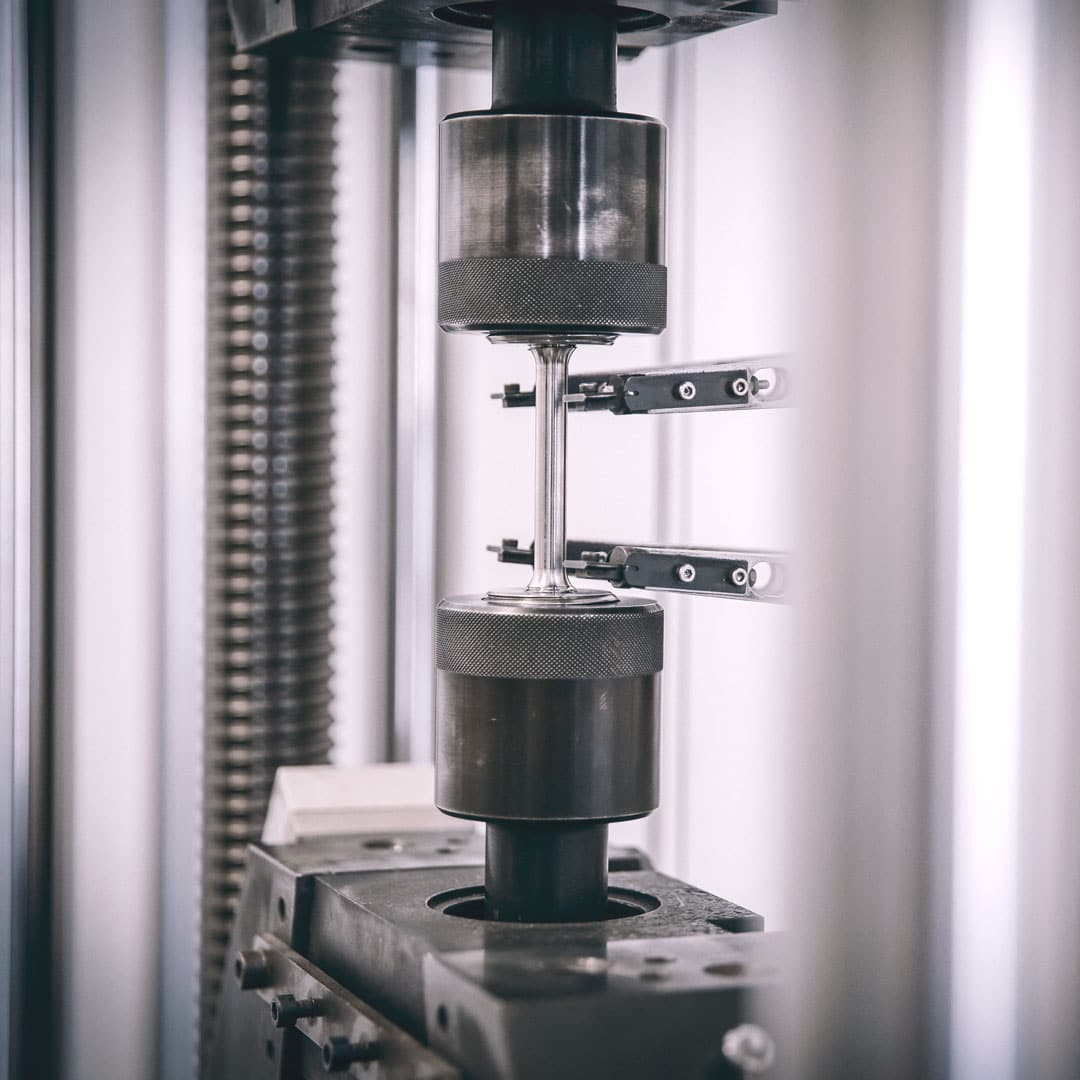

Destructive material testing

- Tensile test at RT according to DIN EN ISO 6892-1 and ASME SA 370

- Tensile test at elevated temperature up to 650°C in accordance with DIN EN ISO 6892-2 and ASME SA 370

- Charpy notched bar impact test from +100°C to -100°C and at -196°C in accordance with ISO 148-1 (lateral expansion, percentage sliding fracture, K/T curves)